THIS JUST HAPPENED: Tesla Fixed My Cybertruck With Glue—And It’s Stronger Than Ever

When a £70,000 electric beast breaks, you don’t expect a tube of adhesive to save it. But Tesla just proved the future of automotive repair doesn’t involve welding—it involves glue.

When his Cybertruck suffered damage to the rear casting—a section so crucial it supports suspension, structural alignment, and safety systems—the owner thought it was totaled. What followed wasn’t just a fix. It was a masterclass in futuristic vehicle repair.

And yes—it involved glue.

The Break That Shook the Beast

The damage looked serious. A rear-end hit had cracked into the Cybertruck’s GigaCast structure, the massive single-piece aluminum casting that holds much of the vehicle’s body together.

Traditionally, this would mean a complete rear section replacement, possibly involving a frame-off rebuild. Repair costs? Likely in the $30,000–$40,000 range, and weeks of downtime.

Instead, Tesla had another idea.

“We’re going to glue it back together,” the service rep said. “And you’re going to love it.”

GigaCast Sectioning: The Future of Repair

Tesla’s solution wasn’t just clever—it was revolutionary. The Cybertruck’s casting design includes strategic cut lines, allowing damaged portions of the vehicle to be cleanly sectioned and replaced, rather than removing the entire cast.

It’s called GigaCast sectioning. And it’s Tesla’s answer to the complexity of monolithic cast parts in EV construction.

Key to this process? A structural adhesive called Fuser 2098—a product so advanced, it can rival weld strength, while offering:

Flexible curing times

Precise bond-line control using micro glass beads

Wider surface adhesion for better load distribution

No heat warping, unlike welding

Adhesive Repair That Can Lift a Truck

Skeptical? So was the owner—until the test.

After completing the repair, the Tesla team used a crane to lift the entire Cybertruck by the section held together with adhesive.

The result? No creaks. No flex. No failure.

“It held stronger than the original welds,” the owner said, visibly stunned.

The structural adhesive wasn’t just strong—it was transformative.

Cybertruck Engineering: Modular, Repairable, Resilient

The repair didn’t stop at glue. Tesla’s process includes:

Hybrid bonding: rivets plus adhesive for added mechanical hold

Tailgate tower realignment: a crucial step to ensure body panel fit and suspension geometry

Energy absorbers: modular aluminum components designed to crumple in a crash—easy to replace, cheap to source

Aluminum e-coat and paint protection: guarding against galvanic corrosion between mixed metals

Tesla also made repair guides publicly available, allowing owners and independent shops to follow precise steps with proper safety precautions. No gatekeeping. No hiding behind proprietary walls.

Safety and Cost: The Two-Headed Win

The final repair bill?

$13,994.

Not cheap—but far below the estimated cost of full casting replacement. And for a vehicle as advanced as the Cybertruck, it’s a staggering win in affordability and turnaround time.

The repair took a few days, not weeks. The adhesive took 24 hours to fully cure, during which final assembly was completed.

The Glue That Redefines Automotive Repair

Tesla’s use of Fuser 2098 is more than clever—it’s a glimpse into the post-weld future of bodywork.

Traditional steel panels? Replaced by cast aluminum.

Spot welds? Replaced by precision adhesives.

Full frame repairs? Replaced by targeted sectioning.

This is Formula 1-level technology making its way into production vehicles—and it’s a game-changer.

Cybertruck: Not Just Tough. Smart.

The Cybertruck isn’t just a steel wedge on wheels.

Its design includes:

Three-layer safety architecture

Rear air suspension with compressor integration

High-voltage interlock loop for safety shutdowns during damage

Built-in diagnostics for quick fault detection

Smart battery layout with six high-capacity modules

And now, a proven repair strategy that uses glue—and wins

Tesla Isn’t Just Building EVs. It’s Rebuilding Repair Itself.

This isn’t just about fixing one car.

This is about democratizing repair—reducing waste, saving time, and putting innovation into the hands of everyday owners.

Tesla’s strategy isn’t to make unbreakable cars. It’s to make cars that are designed to be fixed—efficiently, affordably, and without needing to rebuild from scratch.

Final Words: When the Future Breaks, You Don’t Need a Torch. You Need a Tube.

It’s easy to scoff at the idea of gluing a supertruck back together.

Until you see it work.

Until you see it lift itself off the ground with nothing but adhesive holding the repair.

Until you realize this isn’t gimmick—it’s engineering brilliance.

Tesla didn’t just fix a broken Cybertruck.

It proved that modern cars don’t need to be written off when they break.

And for once, the most important tool in the repair kit wasn’t a wrench or welder…

It was glue.

And it just might hold the future together.

News

DOLLY PARTON’S $20 MILLION PROMISE: THE COUNTRY LEGEND WHO TURNED GRIEF INTO GRACE — AND REKINDLED AMERICA’S FAITH IN LEGACY

THE CALL THAT CHANGED EVERYTHING The morning it broke, America didn’t quite know what to do with itself.No scandal. No…

THE FOOTAGE THEY TRIED TO ERASE: THE FINAL MINUTES OF CHARLIE KIRK — AND THE DOCTOR WHO BROKE HIS SILENCE

THE VIDEO THAT SHOULDN’T EXIST It began at 3:14 a.m. — with an upload to a private Telegram channel called…

The Betrayal of a Patriot: A Cinematic Conspiracy Unraveled

The stage was set in the heart of Phoenix, Arizona, under a blazing desert sun. The air crackled with anticipation…

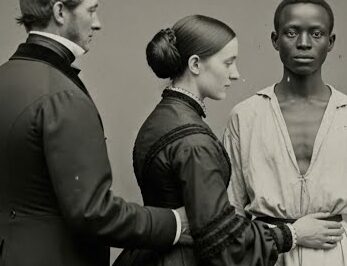

The 𝐇𝐞𝐫𝐦𝐚𝐩𝐡𝐫𝐨𝐝𝐢 Slave Who Was Shared Between Master and His Wife… Both Became Obsessed (1851)

In the sweltering August of 1851, the tobacco fields of Southside Virginia held secrets far darker than the thick red…

Rich Young Master Spends Money To Force Black Maid To Crawl Like A Dog Just For Fun – Her Reaction Shocks Everyone…

Morning in Bell Ridge always arrived polished—dew on clipped lawns, a flag snapping above City Hall, white magnolias leaning over…

She Was Fired for Helping a Veteran’s Dog! Minutes Later, Marines Stormed the Café

The morning light over Mason, Georgia, looked cooler than it felt—silver on storefront glass, a flag lifting over the courthouse,…

End of content

No more pages to load