NO STOPS. NO PAUSES. JUST PURE, RELENTLESS INNOVATION.

In the heart of Texas, just outside Austin, sits a structure so advanced, so fast-moving, it’s forcing the entire global auto industry to rethink everything it knows about manufacturing.

It’s not a factory.

It’s not a plant.

It’s a machine that builds machines — and it now produces a car every 40 seconds.

Welcome to Tesla Giga Texas — where speed meets scale, and Elon Musk’s vision for industrial revolution 2.0 is happening in real time.

🏗️ THE FACTORY THAT THINKS FOR ITSELF

Forget traditional assembly lines. Giga Texas runs on a symphony of AI, robotics, and autonomous systems that operate 24/7 with minimal human oversight.

Gigapress machines stamp full car underbodies in one motion, compressing 10,000 tons of pressure in milliseconds.

Robotic arms, powered by deep learning, adapt their movements with each cycle, continuously refining their efficiency.

Self-guided AGVs (Automated Guided Vehicles) move silently across the floor, delivering components with zero human direction.

This isn’t just speed. It’s intelligence — encoded into steel and silicon.

“We’re not building cars. We’re building how the world will build everything next,” a Tesla executive said during a private tour.

🔋 NO MORE WAITING: 400+ MILES IN ONE REFUEL, FIVE MINUTES FLAT

While other companies are struggling to scale EVs, Tesla is shifting the curve with new battery architecture.

The 4680 battery cells, produced onsite, deliver more range and faster charging.

Vehicles roll out of the factory fully integrated with hardware and software, requiring minimal post-assembly tuning.

In testing, the Model Y produced at Giga Texas consistently hits over 400 miles of range — with future variants aiming higher.

And refueling? When hydrogen tech matures (which Tesla is now watching closely), expect battery-to-fuel convergence at a speed no one else is ready for.

🌎 ZERO EMISSIONS, ZERO EXCUSES: THE GREEN FACTORY MODEL

Giga Texas isn’t just fast — it’s sustainable.

Powered by solar fields surrounding the structure

Built with water recycling systems to reduce industrial runoff

Designed with natural airflow corridors to reduce energy consumption

Tesla’s commitment isn’t just to vehicles — it’s to making factories that don’t cost the Earth.

“We can’t just build clean cars in dirty buildings,” Musk said. “The process matters as much as the product.”

🤖 NOT JUST A FACTORY — A TESTBED FOR AI AND ROBOTICS

While the world watches Tesla’s car output, insiders are focused on something else: Optimus.

A humanoid robot being trained at Giga Texas

Designed to perform basic factory tasks — with an eye on consumer integration

Powered by the same Dojo AI training engine Tesla uses for autonomous driving

This isn’t sci-fi.

It’s the next phase of labor — and Giga Texas is the proving ground.

Musk has hinted that Optimus could soon be as common in homes as smartphones — “a personal robot you trust,” he said.

🚗 TESLA’S COMPETITORS AREN’T JUST WATCHING — THEY’RE WORRIED

Legacy automakers are now playing catch-up.

Ford has restructured its EV roadmap in direct response to Tesla’s pace.

GM is fast-tracking battery plants but still struggles with software integration.

In Germany and Japan, internal reports describe Giga Texas as “a strategic threat.”

And they’re right to worry.

Tesla’s model cuts production time, slashes material costs, and redefines workforce needs — all while boosting scalability.

📈 WHAT COMES NEXT: 2 MILLION CARS PER YEAR — AND BEYOND

Elon Musk has stated clearly: Giga Texas is not the end. It’s the prototype.

Future iterations of the facility are already in development, including next-gen factories in Mexico and Southeast Asia.

Tesla’s ambition is to build a Giga model for every major region — each one tuned to local energy, supply chain, and environmental conditions.

In other words: if Giga Texas is a storm, what’s coming next is a hurricane.

🧭 FINAL THOUGHT: THE CLOCK IS TICKING FOR EVERYONE ELSE

Tesla just proved it can build a car in less time than it takes to heat a cup of coffee.

This isn’t just about production speed. It’s about a complete redefinition of what manufacturing can look like — intelligent, green, decentralized, and adaptive.

Other automakers now face a choice: evolve or fall behind.

Because at Giga Texas, the future is being built — one car every 40 seconds.

⚠️ Disclaimer:

This article is based on publicly available data, Tesla press releases, on-site reporting, and industry commentary. Technical specifications and production rates are subject to change as development continues.

News

DOLLY PARTON’S $20 MILLION PROMISE: THE COUNTRY LEGEND WHO TURNED GRIEF INTO GRACE — AND REKINDLED AMERICA’S FAITH IN LEGACY

THE CALL THAT CHANGED EVERYTHING The morning it broke, America didn’t quite know what to do with itself.No scandal. No…

THE FOOTAGE THEY TRIED TO ERASE: THE FINAL MINUTES OF CHARLIE KIRK — AND THE DOCTOR WHO BROKE HIS SILENCE

THE VIDEO THAT SHOULDN’T EXIST It began at 3:14 a.m. — with an upload to a private Telegram channel called…

The Betrayal of a Patriot: A Cinematic Conspiracy Unraveled

The stage was set in the heart of Phoenix, Arizona, under a blazing desert sun. The air crackled with anticipation…

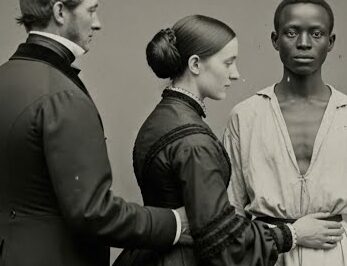

The 𝐇𝐞𝐫𝐦𝐚𝐩𝐡𝐫𝐨𝐝𝐢 Slave Who Was Shared Between Master and His Wife… Both Became Obsessed (1851)

In the sweltering August of 1851, the tobacco fields of Southside Virginia held secrets far darker than the thick red…

Rich Young Master Spends Money To Force Black Maid To Crawl Like A Dog Just For Fun – Her Reaction Shocks Everyone…

Morning in Bell Ridge always arrived polished—dew on clipped lawns, a flag snapping above City Hall, white magnolias leaning over…

She Was Fired for Helping a Veteran’s Dog! Minutes Later, Marines Stormed the Café

The morning light over Mason, Georgia, looked cooler than it felt—silver on storefront glass, a flag lifting over the courthouse,…

End of content

No more pages to load