PART 1

I watched Rick Powell delete eighteen months of my work with one mouse click. He stood at the front of the conference room, finger hovering over that delete key like he was disarming a bomb. Thirty‑two guys from operations watched in dead silence. My turkey sandwich was getting cold in my hand. And that smug smirk kept spreading across his face.

“Cole’s Client Intelligence System,” he announced, reading my folder name off the projector screen. “Or as I like to call it, eighteen months of time‑wasting social work.”

The screen blinked. Gone. Every piece of operational intel I’d gathered, every client note that had prevented contract losses, every driver insight that had improved delivery efficiency—deleted like it never existed.

“No need to clutter the server with this fluff,” Rick said, scanning the room. “Let’s stick to real metrics next quarter.”

That’s when my phone started buzzing in my jacket pocket. Unknown number, but something told me to check it. The call that changed everything.

But let me back up. You need to understand how I got to that moment, watching my commanding officer—because that’s what Rick thought he was—execute my work in front of the entire team.

Eighteen months earlier, I’d joined Brooks Logistics as a freight coordinator. Eight years Navy logistics, two tours managing supply chains in places where one missed delivery could cost lives. I figured civilian freight in the U.S. would be straightforward after coordinating equipment drops in Afghanistan. Wrong. The first week nearly made me quit.

Route tracking, delivery confirmations, client complaints—same problems cycling every week like a broken record. Equipment delays at construction sites. Timing conflicts at manufacturing plants. Frustrated drivers dealing with unreasonable customers. Nobody connecting the dots, nobody preventing the same failures from repeating.

Rick Powell was already my supervisor then. MBA from a prestigious school, ran operations like a factory assembly line. If it wasn’t in the manual, you didn’t touch it. Simple rule: follow protocols, hit metrics, don’t improvise.

But I started noticing patterns that reminded me of convoy operations overseas. When your intelligence is bad, people get hurt. When you don’t understand the human factors affecting your mission, equipment fails and objectives get missed.

A crane operator calling in sick every Friday—turned out his kid was having seizures and he couldn’t leave during school hours. A construction site complaining about early deliveries—their safety briefings ran long because of new OSHA regulations. A manufacturing plant missing pickup windows—the plant manager was dealing with his father’s cancer treatments and couldn’t focus on scheduling.

Standard operating procedure was to file complaints, note the problems, and blame external factors. We lost the Morrison Construction account my second month. No analysis, no post‑mission review. Rick’s assessment: “Not a good fit anyway.”

But the site foreman had told me exactly what went wrong. Our drivers kept showing up when his crane operator was unavailable, creating safety hazards and schedule conflicts. Timing issue. Fixable with basic situational awareness.

So I started my own intelligence file. Not emotions—operational factors. Family situations affecting performance. Equipment schedules impacting delivery windows. Site‑specific requirements the official system ignored.

When Kenny Walsh mentioned his regular construction route supervisor was getting married and would be distracted for two weeks, I logged it, quietly adjusted delivery protocols. The guy came back specifically requesting Kenny for the next month’s runs.

Another client mentioned their plant foreman was retiring and the replacement was inexperienced. I flagged it, briefed our drivers on extended communication protocols and extra verification procedures. What could have been a relationship reset became stronger coordination.

I wasn’t being soft. I was applying basic military intelligence principles: know your operational environment, understand personnel factors, anticipate problems before they become mission failures.

Rick caught wind after a few months. “Don’t waste time on side chatter, Brennan. You’re not their counselor.”

I nodded, kept my expression neutral. “Copy that.” But I didn’t stop. I just got more tactical about information gathering.

The more intel I collected, the clearer the picture became. These weren’t customer‑service notes. They were operational threat assessments. A foreman under family stress makes poor safety decisions. A crane operator worried about job security cuts corners on procedures. A plant manager dealing with medical emergencies can’t maintain focus on efficiency protocols.

One Tuesday morning, reviewing missed confirmations, Tony Romano called in—ice cream distribution, eight‑year client, solid relationship. Something in his voice sounded different: flat, distracted.

“Order numbers look off,” he said. The tone carried that thousand‑yard stare I recognized from people dealing with personal loss. While we worked through logistics, he mentioned it as if it were weather data: “My old man passed last week.” Then he kept talking delivery schedules.

After the call, I updated his client profile: Family bereavement—father deceased. Recommend flexible billing timeline; avoid pressure tactics next two weeks. Then I did something Rick would have written me up for: sent a simple card. Nothing fancy—“Thinking of you and your family during this time. —Cole at Brooks Logistics.”

A month later, Tony upgraded to our premium express service. No rate negotiation, no promotional push. He just signed and said, “Appreciate you guys being solid.” That’s when I understood this wasn’t guesswork anymore. This was operational intelligence producing measurable results.

The real test came with Maggie O’Brien’s vineyard operation—a boutique winery in Oregon. Delivery delays triggered her like incoming mortars. She’d once threatened to terminate our contract because a shipment of custom bottles arrived with minor damage.

Weather delays hit her route hard one month. She filed a formal complaint that could have cost us the entire West Coast wine distribution contract. I called her directly, provided a detailed situation report, acknowledged the impact on her production timeline. Then I mentioned I’d seen a trade‑magazine feature on her latest vintage—impressive achievement for a small operation.

“ You actually read that article,” she said. A week later, she upgraded to climate‑controlled premium service. No sales pressure, no promotional offers. This wasn’t customer relations. This was strategic intelligence producing quantifiable improvements.

Back in that conference room, my phone was still buzzing. Rick was still smirking at the empty screen where my work used to be.

Drivers started noticing the operational improvements too. Kenny Walsh used to complain every time I assigned him the Denver construction route. Said the site supervisor was aggressive and unreasonable, made every delivery feel like walking through a minefield. I called the supervisor, listened to his actual concerns. He wasn’t unreasonable—he was frustrated because morning deliveries disrupted his crew’s mandatory safety briefings. New OSHA regs required extended protocols, and early arrivals created conflicts that affected compliance.

Simple fix: shift Kenny’s delivery window back three hours. Next time he ran Denver, he came back with a different story. “Guy actually thanked me for being flexible. Asked about my family, offered coffee.” Complete turnaround. After that, Kenny specifically requested Denver every Friday. Same client, same requirements—different operational understanding.

They weren’t naive. The drivers, the clients, the site supervisors—they all recognized when someone was paying attention to reality instead of just following standard protocols. But Rick noticed too.

During our quarterly review, he pulled me aside. “This popularity‑contest approach you’re running, Brennan—it’s not professional. It’s not scalable.”

I kept my expression neutral. “Client satisfaction scores are up thirty‑eight percent in my sector.”

“That’s not the point.” He stepped closer, trying to establish dominance by proximity. “You’re making this department look unstable. Clients shouldn’t expect emotional hand‑holding.”

“Operational intelligence isn’t emotional, Rick. It’s tactical.” His jaw tightened. “Stick to standard communication protocols. No more improvisation.”

I nodded. “Copy that.” But the results kept coming. Client retention improved. Delivery efficiency increased. Driver satisfaction went up across all my routes. Hard to argue with quantifiable success.

PART 2

When the annual regional meeting rolled around, I knew what was coming. Big conference room, stale coffee, Howard Lancaster in his standard navy blazer delivering corporate updates. I sat with the operations team, watching PowerPoint slides about fuel costs and route optimization.

Then Howard clicked to the performance metrics screen: sharp blue line shooting upward. “Client satisfaction has improved forty‑one percent across the Pacific Northwest region,” he announced. “Our highest improvement in seven years.”

Actual applause. Not polite clapping—real appreciation. “Contract renewal rates are up. Multiple clients have voluntarily upgraded service tiers. Driver retention has improved. Operational efficiency metrics show consistent gains.” That familiar feeling from successful convoy ops—mission accomplished. I kept my expression professional. Howard didn’t mention my name. He didn’t need to. Every guy in operations turned to look at me. Even the ones who used to roll their eyes when I asked about client family situations or site‑specific requirements.

Rick sat three seats away, arms crossed, foot tapping under the table like he was counting down. After the meeting, he followed me to the break room.

“Let’s discuss your methodology,” he said, closing the door.

“Which methodology?”

“Don’t play dumb, Brennan. You think I don’t know what that presentation was really about?”

“Howard presented regional metrics. Standard quarterly review.”

“This whole emotional‑manipulation routine you’ve been running—it’s unprofessional. You’re making decisions based on feelings instead of data‑driven protocols.”

“Client retention is data. Revenue increase is data. Efficiency improvements are measurable.”

“That’s not what I’m talking about.” He slid a printed memo across the table. “You’re reassigned to special projects. I want a comprehensive analysis of your client‑interaction methods. Every conversation, every note, every deviation from protocol. Full documentation for executive review.”

I stared at the memo. Standard punishment disguised as evaluation. “Time frame?”

“Three weeks. Complete analysis with recommendations for scalable implementation.” He was trying to bury me in paperwork while taking credit for the improved metrics.

“Understood.”

“Just so we’re clear, Brennan—this doesn’t make you irreplaceable. Results are team efforts, not individual achievements.”

I took the memo and walked out. Then I did the work. Three weeks. Late nights. Vending‑machine food and bad coffee. I dug through everything—call logs, delivery records, client feedback, internal communications. Built comprehensive spreadsheets connecting client upgrades to proactive‑communication frequency. Mapped revenue improvements to problem‑solving initiatives. Sixty‑seven pages of documented operational intelligence proving that situational awareness improved client satisfaction and company profitability. Every metric cross‑referenced. Every improvement quantified. Every intervention cataloged.

When I submitted the report, I wasn’t tired. I felt like I’d just completed mission prep for a major operation.

Rick accepted it like routine paperwork. “I’ll review this and provide feedback.”

“Copy that.”

The email arrived next morning. Subject line: Mandatory Training — Communication Protocols Standardization. Rick had reserved the main conference room for two hours. All operations personnel required to attend. I knew exactly what this was. Not training—public execution. I showed up anyway, took my usual position by the windows, second row. Military bearing, professional composure. Whatever he had planned, I’d handle it like any other operational challenge.

Rick stood at the front, hand on the presentation remote, corporate smile that didn’t reach his eyes. “Thanks for attending. Today we’re examining client‑communication methods—what works, what creates inefficiencies, and what represents professional best practices versus personal indulgence.”

Click. My stomach tightened, but I kept my face neutral. On the projector: the front page of my operational analysis. Charts. Metrics. Client‑interaction summaries. All displayed like evidence at a court‑martial.

“Let’s examine some examples of what not to do.” That’s when I understood. He wasn’t just dismissing my work—he was going to publicly humiliate me with it.

My phone buzzed in my jacket pocket. Unknown number again.

Click. Slide two. A client note I’d documented about equipment delivery during family bereavement. He read it aloud in a mocking tone: “Site supervisor requested delivery delay due to family funeral. Confirmed alternative schedule and implemented follow‑up protocol for Monday.” He scanned the room with that corporate‑superiority look. “Seriously? We’re tracking family funerals now? What’s next, birthday parties?”

Dead silence. Nobody laughed.

Click. Another slide. “Crane operator’s son deployed overseas—stress affecting operational performance. Recommend consistent scheduling and clear communication protocols.”

Rick smirked. “Are we running a logistics company or a counseling service?” Still nobody laughed. I caught Kenny’s eye across the room. His jaw was set. So were half the others.

Ten more slides, each twisting operational intelligence into corporate comedy: plant‑manager retirement planning; foreman safety concerns. Every piece of information that had prevented problems or strengthened relationships turned into ammunition for his efficiency theater.

“These are operational distractions,” Rick declared. “This kind of hand‑holding creates unrealistic client expectations. Our job is logistics coordination, not life coaching.”

Final slide: my revenue‑correlation chart showing the direct connection between proactive communication and contract renewals. Forty‑one percent improvement in client satisfaction. Quantifiable results. He ignored the numbers completely. He hovered his mouse over the shared‑drive folder.

“I’ve decided this database creates unnecessary complications.” One click. Delete. “Server space is expensive. Starting next quarter, we’ll focus on measurable metrics only.”

Complete silence. Thirty‑two guys watched their supervisor delete proven operational improvements because they didn’t fit his model.

My phone buzzed again. Same unknown number. I stood up, stepped toward the door like I was heading to the restroom, and kept walking to the hallway.

“Cole Brennan.”

“This is Pat Sullivan, Apex Freight Solutions. You got five minutes?”

I pressed my back against the wall, watched through the glass as Rick kept talking. “You’ve got three.”

She laughed—genuine, not corporate‑fake. “Fair enough. Direct approach—we’ve been tracking your operational results at Brooks. The client‑intelligence system, that’s your development, correct?”

I didn’t confirm immediately.

“We’ve interviewed six clients who renewed or upgraded this year. They all mentioned you specifically. Also spoke with four drivers who transferred to our company from Brooks. Same feedback.” My pulse stayed steady, that pre‑mission focus kicking in.

“What’s the offer?”

“Director of Client Operations. Base salary ninety‑five thousand. Profit sharing, equity options. Remote flexibility when needed. You build your team using whatever methods work.”

“No hesitation: you asking me to bring client data or internal information?”

“Negative. Just asking you to keep being exactly who you are.”

That was it. No extended sales pitch. No multi‑round interviews. Just someone who understood operational value without needing a PowerPoint.

“I accept.”

“Contract’s ready for digital signature. Can start Monday if you want.”

“Send it.” I hung up and walked back toward the conference room.

PART 3

Rick was still talking about streamlined communication protocols and standardized efficiency metrics, like he hadn’t just eliminated the system that produced the best quarterly results in seven years. I stepped into the projector light and faced the room, the same calm I’d felt before convoy ops—clear thinking, decisive action.

“Quick announcement,” I said, voice carrying to the back wall.

Rick’s mouth snapped shut.

“I’m resigning from Brooks Logistics. Effective immediately.”

Half the room looked confused. The other half processed tactical intel they hadn’t expected.

Rick forced a light laugh. “That’s not how resignation procedures work, Brennan. You’ll need to submit proper documentation through Human Resources—”

I pulled out my phone, opened the contract, and turned the screen toward him. “Apex Freight Solutions. Director level. Already signed.”

He reached for my phone like he had authority. I pulled it back. “I don’t need your approval, Rick.”

From the corner, Howard Lancaster stood without a word, straightened his blazer, and slipped out like he wanted no part of what was about to happen.

Rick stepped forward, trying to regain control. “You can’t just abandon your responsibilities without proper transition procedures.”

“Watch me.” I turned to the team. “For anyone interested in working somewhere that values operational intelligence over corporate theater, you know how to reach me.”

I didn’t wait for responses. I walked out with the same bearing I’d used leaving firebase briefings—mission complete, moving to the next objective.

The elevator opened at Apex Freight’s downtown office—clean space, industrial design, people moving with purpose instead of corporate fear. Every person I passed nodded like I’d already earned my place there.

Pat Sullivan came out of her corner office with both hands extended. “Welcome to your operation, Cole.”

My office had real walls, not cubicle partitions. The nameplate read Director of Client Operations. I dropped my gear, opened a new spreadsheet, and started building protocols.

Two hours later, my phone rang. I didn’t recognize the number, but the name made me sit up straight.

“Maggie O’Brien.”

“The vineyard.”

“Cole Brennan.”

“Knew you’d answer direct,” she said, relief in her voice. “Didn’t have to navigate some phone‑tree maze.”

“What can I do for you, Maggie?”

“Don’t suppose Apex handles high‑maintenance wine operations that need specialized logistics and actually competent coordination?”

No pitch required. “You know my methods.”

“Exactly why I’m calling.” By the end of that conversation, we were designing a custom logistics package.

An hour later, Tony Romano called. Said my name appeared on LinkedIn, wanted to see if I’d landed somewhere that understood operational excellence. I didn’t have to explain Apex’s capabilities. He wanted to transfer his entire Midwest distribution network.

The third call came from a regional equipment company that had been lukewarm with Brooks for years. Minimal communication. No upgrades. “Cole,” the operations manager said, “you’re the coordinator who remembered my plant supervisor was dealing with his wife’s cancer treatments.”

“Rodriguez. Dialysis schedule, Tuesdays and Thursdays.”

Silence for three seconds. “How quickly can we move our contracts to Apex?”

By the end of week one, I had seven contract transfers in progress. No cold calling. No pressure sales. Just clients who remembered what professional coordination actually looked like.

Meanwhile, intel filtered back from Brooks. Rick was scrambling, trying damage‑control. He started sending ‘personalized’ outreach emails to key clients—except they weren’t personal. Standard templates with mail‑merge fields that sometimes contained the wrong information.

One client forwarded me Rick’s email with a note: Thought you’d find this interesting. Subject line: We miss working with you—but it referenced equipment that company hadn’t used in two years. Another mentioned a plant supervisor who’d transferred to a different facility six months prior. Templated efficiency meeting operational reality. Predictable results.

Word travels fast in U.S. logistics circles. Apex didn’t offer discount rates or pressure‑sell premium services, but feedback was spreading on trade forums and LinkedIn. They actually understand operations kept appearing in comments. Every time someone called me, they came in already convinced. They remembered the crane operator’s name, the plant supervisor’s schedule changes, the foreman’s safety‑protocol concerns. All I had to do was answer the phone and deliver what I’d always delivered: attention to the factors that actually affect business success.

By week four, Pat stopped looking surprised when projections came in. “Fifty‑two percent growth,” she said, reviewing her tablet. “Month‑over‑month client acquisition.”

I was finalizing another onboarding checklist. “Give it two more weeks. Maggie’s expanding into California. Tony just asked about exclusive routing for Colorado.”

She grinned. “Cole, you’re not building a client roster. You’re building an operational network.”

She wasn’t wrong. Halfway through first quarter, transfers kept accelerating—small regional accounts, mid‑size distributors, then the major accounts that get industry attention. Maggie’s vineyard operation and Tony’s distribution both formally terminated their Brooks contracts.

Maggie posted on LinkedIn the same day. Professional. No names. But she thanked “the logistics coordinator who treated our operation like it mattered, not like account number forty‑seven.” Tony commented with a thumbs‑up.

Pat stuck a note to my monitor that afternoon: Keep executing.

Same day, someone forwarded another Brooks email—this one from Rick himself—offering temporary rate reductions and “personalized attention from senior management.” Standard corporate panic. Nobody replied. Not one client.

PART 4

Three months in, industry gossip confirmed what I’d expected. Brooks was hemorrhaging contracts across multiple sectors. Rick had been called into emergency board reviews twice in one week.

A former colleague texted late one evening: You didn’t hear this from me, but the board’s investigating operational decisions from the past year.

I’d heard enough. Rick tried claiming I was actively recruiting Brooks clients, but the timeline cleared me completely. Every contract I’d signed, every call I’d taken—clients initiated contact. Most within hours of that conference‑room demonstration, some the same day. The operational data cleared me. The same data buried Rick’s defense.

A month later, Pat handed me a printout during morning briefing. “Rick’s final strategic move,” she said. Mass email to Brooks’ remaining client base, offering emergency rate cuts and executive oversight of all delivery operations. Nobody responded.

That was the last time his name came up in professional conversation. Truth was, I didn’t need revenge operations. Didn’t need to sabotage anyone or burn bridges. He handled that himself, one deleted file at a time. I just gave clients an alternative, and they made their own tactical decisions.

Four months later, reviewing quarterly performance reports, my assistant knocked on the door. “Call from Howard Lancaster,” she said. “Claims it’s an urgent operational matter.”

I hadn’t heard that name since the day I walked out of Brooks. “Put him through.”

Howard came on smooth and diplomatic. “Cole, hoping we can discuss potential collaboration opportunities that benefit both organizations.”

“Didn’t realize we were still operating in the same sector, Howard.”

He gave that executive chuckle leaders use when they’re trying to project confidence while treading water. “Brooks has experienced some challenging market conditions. We’ve reevaluated certain operational approaches and would like to offer you a senior leadership position.”

I leaned back, watching afternoon traffic through my office windows. “Continue.”

“Senior Vice President of Strategic Operations. Complete autonomy over client relations, team development, methodology.”

“Compensation?”

“Double your previous Brooks salary, plus performance bonuses and equity.”

“Additional considerations?”

“Full departmental authority. Your recruitment choices. Your structure. We’re prepared to be extremely flexible.”

I let the silence stretch until it turned uncomfortable. “Howard, Apex provided all of that before it became a desperate necessity.”

He cleared his throat. “I understand, but I don’t think you’re appreciating the full scope of what Brooks is offering.”

“I think I’m appreciating it perfectly.”

“Cole, this represents a significant opportunity to—”

“Howard, I’m not returning to Brooks.”

He didn’t argue. Just quiet acknowledgment and a click.

Six weeks later, Brooks announced layoffs affecting forty percent of operations personnel. Industry news confirmed they sold two regional divisions to a Chicago‑based firm nobody recognized. Rick’s name wasn’t mentioned in the remaining org chart. Someone forwarded me his updated LinkedIn profile: Operations Consultant — Process Optimization — Available for project‑based engagements. No mention of Brooks. No management titles. A generic headshot and a list of vague achievements.

The same day that news broke, Pat called me into her office. “We want to formalize your position,” she said, sliding a contract across her desk. Apex Freight Solutions at the top, and a title: Managing Partner, Strategic Operations Division.

I signed before sitting down.

The office I used to occupy was just a workspace. Now I commanded an entire floor—full team, complete strategic autonomy. Real authority, not theater. And I didn’t chase business anymore; it came to us. Every renewal happened because clients trusted our capabilities. We knew their equipment schedules, their personnel situations, their site‑specific requirements. We showed up when competitors were still following scripts.

Industry messages started arriving regularly—not from clients, from former Brooks personnel. Simple requests, mostly. Any openings available? You were right about operational intelligence. Wish I’d followed your lead. I hired when positions opened, building the kind of operation I’d always wanted to run.

The perfect part was, I never had to destroy anything. Rick handled that mission himself, one efficiency protocol at a time. His obsession with standardized metrics blinded him to a simple truth about American logistics: People don’t stay because you follow procedures. They stay because they know you understand their operational reality.

No lawsuits. No public scenes. No viral confrontations. Just contracts quietly transferring from one company to another, one satisfied client at a time.

Now when I walk Apex’s operations floor, I see evidence of what works: photos of drivers’ families on workstations, notes about client schedules, updates on plant‑manager retirements and safety‑officer concerns. Every client file contains operational intelligence that isn’t about revenue projections. It’s about understanding the human factors that affect mission success.

When emails arrive starting with You probably don’t remember this, but…—I do. Every single operational detail. Rick thought it was inefficient social work. I proved it was strategic advantage. And the best part? I never needed revenge.

News

He fired his maid six years ago. At the airport, he saw her shivering with two kids. Then the little boy smiled and said a name that destroyed him.

He Fired His Maid Six Years Ago. Today, He Saw Her at the Airport, Shivering, With Two Small Children. Then…

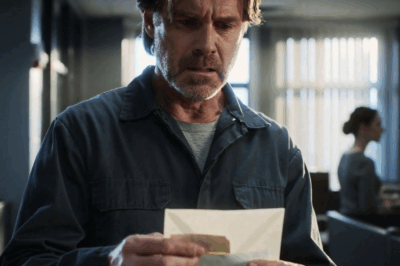

THE ENVELOPE SAID “24 HOURS.” WHAT I FOUND NEXT…

Part I My boss had never called me into his office without warning, and he had never looked afraid of…

“21 years of loyalty “— and they threw me out like trash. But they forgot one tiny detail in the paperwork…

Part I At 6:47 a.m. on a Tuesday that would change everything, I was flat on my back in a…

My Parents Sued to Evict Me So My Sister Could “Own Her First Home.” In Court, My 7-Year-Old Asked…

Part I My parents sued to evict me so my sister could own her first home. In court, my seven‑year‑old…

I Found a Receipt That Said “Come Back When You’re Ready.” So I Did.

Part I I was cleaning out my wallet when I found a receipt from a café I didn’t recognize. It…

Little Black Boy Gave Silent Signal To Police Dog – What It Found Next SHOCKED Everyone

Part I Sergeant Rex halted mid‑stride inside the central concourse like he had seen a ghost. His ears lifted, tracking…

End of content

No more pages to load